Introduction

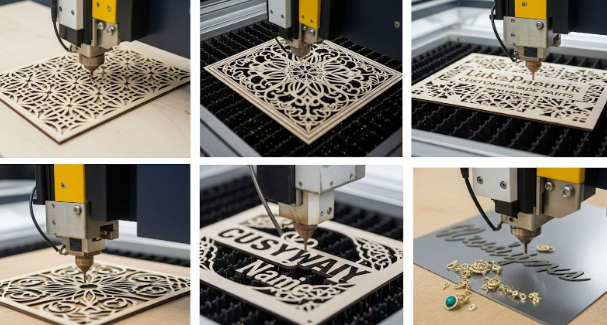

Kitchener entrepreneurs, whether based in a workshop, design house, or small fabrication facility, the laser cutting market is abuzz. It’s emerging quickly—not only abroad, but in Canada as well. If you are considering investment in laser cutting or already own a machine, possessing an awareness of the market trends will assist you in making more intelligent decisions and remaining competitive.

1. The Canadian Market Is Evolving Quickly

The Canadian laser processing industry, encompassing laser cutting, engraving, and other technologies of this ilk, is on a steep ascent. It’s expected to grow nearly to double in the decade ahead, from just over two billion dollars presently to over four billion by 2030. A further research estimate puts the figure even higher, with Canada’s laser machining industry reaching nearly ten billion by the year 2033.

It is demand-pull in all such industries like automotive, aerospace, consumer products, and construction. Organizations need shorter lead times for manufacturing, higher tolerances, and higher individualization. Laser cutting technology does all these.

For Kitchener shops, this trend constitutes a constant series of opportunities. Customers are becoming more eager for partners who can provide precision and flexibility without introducing long lead times. Shops who already have experience working with laser cutting are in a good position, and those who want to integrate it will have the investment facilitated with this type of demand.

2. Global Trends Point to Innovation and Automation

Worldwide, the market for the laser cutting machine is already in excess of six billion dollars and will increase more than twofold in eight years. It is being driven by the same pressures Canadian companies are experiencing: demand for greater accuracy, automation, and the integration of machinery with electronic processes.

Laser cutting is not considered to be the preserve of giant manufacturers anymore. Due to the progress made in software and machine design, it is now within reach for small and medium-sized workshops to pursue as well. It has brought about a level playing ground where a small Kitchener shop is at par with much larger ones.

Automation is another part of the equation. Machines are able to work more hours and with fewer direct human contacts. Coupled with CAD programs and intelligent design packages, this is a quicker route from idea to end product. All of these world trends mean that for Kitchener businesses, staying ahead of technology will be able to make a significant difference in efficiency and competitiveness.

3. What This Means for Kitchener Businesses

More Market, More Competition

As the market grows, more and more companies will be applying laser cutting, so uniqueness is most crucial. Having something new in service, design possibilities, or specific cutting for specific industries is what will differentiate your business. Simply providing “laser cutting” is not going to be enough because the service gets commoditized.

ROI Is Important

Laser technology is expensive. Industrial systems for entry point can range from fifty thousand to over three hundred thousand dollars. The expense may be justified when the payoff comes in increased efficiency, reduced waste, and the ability to perform jobs previously out of reach. The key is to maximize the use of the machine. Sitting equipment is expensive, but a machine that is well-booked will pay for itself sooner than expected.

Side Businesses vs. Full-Time Stores

The availability of lower-cost hobby-sized machines has brought about an increase in side ventures, as individuals cut and engrave materials for neighborhood craft fairs or internet retailers. Though it has created more competition, it also raised the awareness among customers for what laser cutting can accomplish. Full-time businesses continue to enjoy the upper hand in doing large jobs, reliability, and providing professional quality. Scale and dependability are the determining factors.

Local Cost Insights

Ontario production plants indicate paying between one hundred and one hundred and twenty dollars an hour for laser cutting, plus material surcharges on top. These charges will vary based on the level of complexity, set-up, and material. For businesses in Kitchener, this is a reasonable benchmark when you’re billing your fees. Having some idea of local average rates can keep you from undercharging while keeping you competitive.

4. Why Kitchener Is Ideally Suited

Tech Ecosystem

Kitchener-Waterloo has long been famous for technology and manufacturing prowess. The area is served by engineers, skilled tradespeople, and inventors who know how to leverage new technologies such as laser cutting. This ecosystem provides local companies with a support structure that not all cities can provide.

Local Demand

Industries that are most dependent on laser cutting—automotive, electronics, construction, and architectural—are all present in the area. That inherent demand is the reason that Kitchener is such an attractive destination for facilities wanting to invest in this equipment.

Community Advantage

Networking in the Kitchener business environment offers an extra push. Trade shows, local networking meetings, and industry associations offer store owners the opportunity to learn from each other, exchange resources, and even work together on bigger projects. It is just such a feeling of belonging that makes the whole market stronger and enables individual businesses to expand.

Conclusion

If you are a businessman or manager in Kitchener, the laser cutting Kitchener industry is opening up in high style. Markets are growing, and companies that invest sensibly in equipment, technology, and efficiency have much to gain.

Your advantage won’t be in the largest or the most powerful machine—it will be in the superior ideas. Target special work, establish a good rapport with your customers, and fine-tune your operation. That way, you can surf the tide of expansion without any fears.