When it comes to industrial piping systems, flanges play a critical role in connecting pipes, valves, pumps, and other equipment. Among the many standards available across the globe, DIN Flanges are one of the most widely adopted types in industries, particularly in Europe. Their precision, durability, and standardization make them essential for a wide range of applications.

In this blog post, we’ll take a deep dive into what DIN Flanges are, how they are classified, the types available, the standards that govern them, and their industrial uses. Whether you’re a plant engineer, a procurement officer, or simply someone interested in industrial fittings, this guide will help you understand everything you need to know about DIN Flanges in a simple, informative way.

What Are DIN Flanges?

DIN Flanges are pipe flanges manufactured according to the standards set by Deutsches Institut für Normung (DIN) — the German Institute for Standardization. These flanges are typically used in European and international piping systems where DIN standards are followed.

The purpose of a flange is to create a reliable seal between two components, and DIN Flanges ensure that this connection is not only leak-proof but also strong enough to handle various pressure and temperature conditions.

Why Are DIN Flanges Important in Industrial Applications?

In industrial environments like chemical plants, refineries, water treatment facilities, and oil & gas systems, flange connections need to be standardized, durable, and safe. This is where DIN Flanges truly shine.

Key Reasons for Their Importance:

-

Standardization: Ensures global compatibility and simplifies procurement.

-

Interchangeability: Easy replacement and maintenance across different equipment.

-

Pressure & Temperature Resistance: Designed to withstand harsh industrial conditions.

-

Variety: Available in multiple sizes, materials, and pressure ratings.

Additionally, partnering with a reliable DIN Flanges Manufacturer guarantees consistent quality and performance, which is essential in mission-critical operations.

Understanding DIN Standards for Flanges

The DIN standard includes a wide range of flange types, each designated with a specific DIN number. These numbers correspond to the design, pressure class, and application. Here are some of the most commonly used DIN flange standards:

| DIN Number | Description | Pressure Rating |

|---|---|---|

| DIN 2573 | Flat Flanges for welding | PN 6 |

| DIN 2576 | Slip-On Flanges for welding | PN 10 |

| DIN 2633 | Welding Neck Flanges | PN 16 |

| DIN 2634 | Welding Neck Flanges | PN 25 |

| DIN 2635 | Welding Neck Flanges | PN 40 |

| DIN 2642 | Loose Flanges | PN 10 |

| DIN 2527 | Blind Flanges | PN 6 to PN 40 |

These DIN standards ensure that the flange dimensions, material, and performance meet regulated requirements.

Types of DIN Flanges

Depending on the application and connection type, there are several types of DIN Flanges used in industries. Here’s a breakdown:

1. Welding Neck Flange (DIN 2633, 2634, 2635)

This type has a long tapered hub that is welded to the pipe. It’s ideal for high-pressure systems and provides excellent stress distribution.

-

Used in: Oil & gas, petrochemicals

-

Pressure Classes: PN 16 to PN 40

2. Slip-On Flange (DIN 2576)

A simple and economical flange, the pipe is inserted into the flange and welded both inside and outside. Not suitable for high-pressure environments.

-

Used in: Low-pressure pipelines

-

Pressure Classes: PN 10

3. Blind Flange (DIN 2527)

These are used to close the end of a piping system. They do not have a bore and are often used for pressure testing.

-

Used in: Process isolation, end closures

-

Pressure Classes: PN 6 to PN 40

4. Socket Weld Flange

Socket weld flanges are designed for small-diameter high-pressure piping. The pipe is inserted into the socket and fillet-welded.

-

Used in: Hydraulic and steam lines

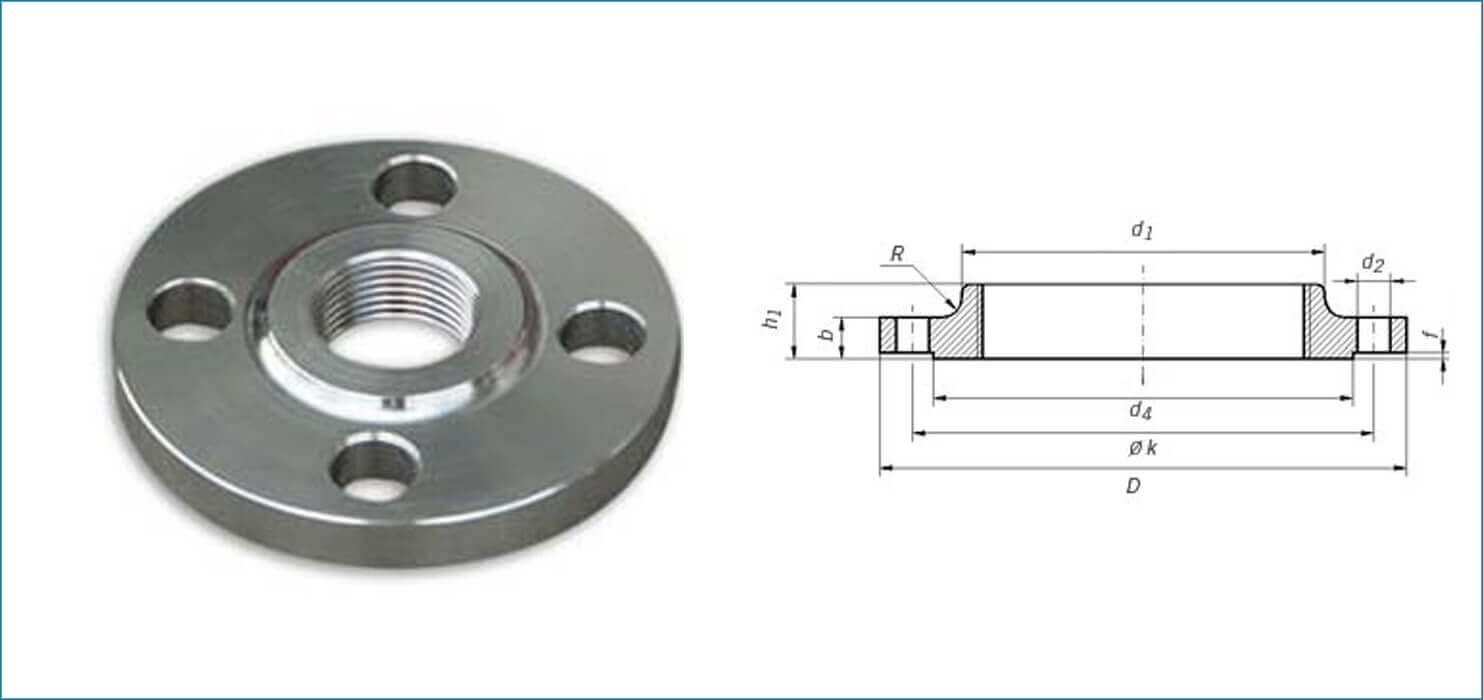

5. Threaded Flange

This flange is threaded and allows the pipe to be screwed in without welding, making it suitable for applications where welding is not feasible.

-

Used in: Small diameter, low-pressure systems

6. Lap Joint Flange (DIN 2642)

Used in systems that require frequent dismantling, these flanges slide over the pipe and are used with stub ends.

-

Used in: Water supply, food processing

Applications of DIN Flanges Across Industries

Thanks to their standardization and versatility, DIN Flanges are used in a wide range of industries. Below are some notable sectors and how they utilize these flanges:

1. Oil & Gas Industry

-

Used for transporting crude oil, natural gas, and refined products.

-

Require flanges that can withstand high pressures and temperatures.

2. Petrochemical Plants

-

Handling aggressive chemicals and high-pressure steam.

-

Use stainless steel and alloy DIN flanges for durability.

3. Water Treatment Plants

-

For connecting pipes in filtration and distribution systems.

-

Generally use PN 10 and PN 16 flanges made of stainless or plastic-coated steel.

4. Food & Beverage Industry

-

Require hygienic piping systems; use stainless steel DIN flanges.

-

Easy to clean and resistant to contamination.

5. Pharmaceutical Manufacturing

-

Precision and cleanliness are essential.

-

Stainless steel DIN flanges meet strict sanitary regulations.

6. Power Generation

-

Flanges used in boilers, heat exchangers, and turbine connections.

-

High-strength and corrosion-resistant materials preferred.

7. Shipbuilding and Marine

-

Resistant to saline environments.

-

Often use Copper-Nickel and Duplex flanges.

Benefits of Partnering with a Trusted DIN Flanges Manufacturer

Sourcing from a reputable DIN Flanges Manufacturer can significantly improve your operational efficiency and safety. Here’s why:

-

Consistent Quality: Ensures product reliability.

-

Custom Solutions: For non-standard sizes and alloys.

-

Technical Support: Helps in proper selection and application.

-

Global Standards Compliance: Assurance of safety and compatibility.

-

Quick Turnaround: Faster delivery with accurate inventory.

Final Thoughts

DIN Flanges have proven their value in modern piping systems due to their standardization, versatility, and robust performance. Whether you are handling chemicals, water, oil, or food products, these flanges ensure a leak-proof and durable connection.

When sourcing flanges, always consider working with a reliable DIN Flanges Manufacturer who understands your industry needs and can supply high-quality products that meet international standards.